rockwell hardness test hra of 25|rockwell hardness chart : purchasers Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as . WEBO RARBG é o melhor site para download de torrents, uma vez que ele possui vários programas de TV, filmes e videogames populares, a maioria dos torrents tem seeders suficientes e todos os torrents são verificados.

{plog:ftitle_list}

Basque pelota is usually played in a two walled court (Basque: frontoi or pilotaleku, French: fronton, Spanish: frontón). As seen in the picture, there are also courts with one wall, a modality prevailing on the French side of the Basque. Ver mais

There are three methods for measuring Rockwell hardness: 1) HRA, using an indenter with diamonds, the measured value of the load is 60 kg; 2) HRC, the measured value with a load of 150 kg; 3) HRB, with a 1/16-inch steel ball indenter, the measured value of the .

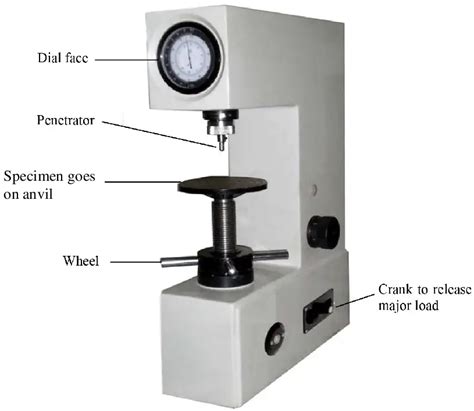

A Rockwell hardness tester. The Rockwell scale is a hardness scale .This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as . In the Rockwell hardness test, an indenter is pressed into the material to be tested. The indentation depth serves as a measure of the hardness! The measuring process of the Rockwell test is carried out in three .

The Rockwell hardness test utilizes 1 of 6 different main loads: In total, this gives 30 different Rockwell scales. Each one is characterized by a different combination of indenter type and main load, and is suitable for a particular material or .The Rockwell hardness number – HR, can be directly displayed on the dial. Indentation hardness measures the ability to withstand surface indentation (localized plastic deformation) and the .

The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. The Rockwell test is generally easier to perform and more accurate than other hardness methods.The Rockwell hardness test continues to be applied as a tool for assessing the properties of a product while the tolerances on the acceptable material hardness have become tighter and .

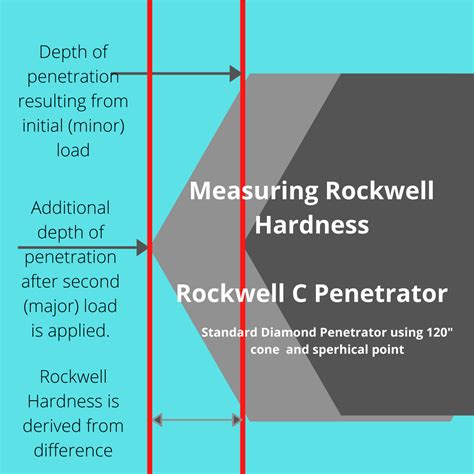

See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .

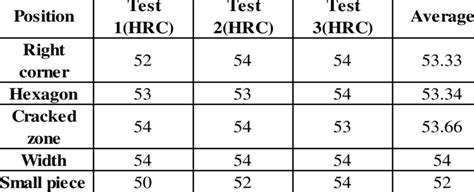

Hardness Test and Application. HRC means Rockwell hardness C scale. HRC and HB are widely used in production. HRC application range HRC 20~67, equivalent to HB225 — 650. If the hardness is higher than this range, Rockwell hardness A scale HRA is used. If the hardness is lower than this range, Rockwell hardness B scale HRB shall be used.Rockwell Hardness Test formula. Your testing equipment will provide an accurate calculation of the Rockwell hardness result, but there’s a formula to calculate the depth that’s measured into a Rockwell hardness number, which .Rockwell hardness test using Rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc, aluminum, cemented carbides, iron, titanium, copper alloys, and certain plastics. . HRA: Spheroconical diamond: 98.07 N (10 kgf) 588.4 N (60 kgf) Cemented carbides .

The Rockwell hardness test continues to be applied as a tool for assessing . increase in the preliminary-force for a Rockwell HRA test... 16 Figure 3: Force vs. time plot (Figure A) and indenter-depth vs. time plot (Figure B) demonstrating the effect of an . test surface of 25 HRC test blocks, illustrating how 3. Rockwell hardness uses the depth of indentation plastic deformation to determine the hardness value index. A unit of hardness is 0.002 millimeters. When HB>450 or the specimen is too small, the Brinell hardness test cannot be used and the Rockwell hardness measurement is adopted instead.The Rockwell scale is one of the standard methods used to measure a material's hardness. The scale has different numbers that represent hardness based on the indent's depth caused by the test material's indentation. Let us look at how you can measure and read Rockwell's hardness value in this article. HRA: Diamond cone: 588.4: 20-88: Carbide, hard alloy, quenched tool steel, shallow case hardening steel . 25~100: Non ferrous metals, malleable cast iron and other materials: C: Diamond circular dimension: 1400: 1500: 100: 20~67: . The Rockwell hardness test is divided into various scales, each with a wide range of applications. .

A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .The Rockwell hardness test is less affected by surface rough-ness compared to other methods such as the Vickers or Brinell . 60 kg HRA HRFW HRHW HRLW HRRW 45 kg (Superficial) HR45N HR45TW HR45WW HR45XW HR45YW 30 kg (Superficial) HR30N HR30TW HR30WW HR30XW HR30YW . HBW 2.5/31.25 2.5 mm 31.25 kgf 306.5 N 5 15.9-109 What is HRA in Rockwell hardness test? HRA is one of the scales in the Rockwell hardness test, specifically using a diamond cone penetrator. . The hardness of EN8 steel can vary depending on the heat treatment, but it is commonly found in the range of 25-35 HRC. See also Celsius, Fahrenheit, Kelvin, Réaumur, . Certaincommercial. entities, equipment, ormaterials. may. be. identifiedin. this. document. in. order. todescribe. anexperimentalprocedure. or. concept. adequately .

25: 0Cr18Ni9: 205: ≦187: 26: 1Cr18Ni9: 205: ≦187: 27: . The Rockwell hardness test uses three different test forces and three different indenters, resulting in a total of nine possible combinations and corresponding Rockwell hardness scales. . The three most commonly used Rockwell hardness scales are HRA, HRB, and HRC, with HRC being . In the Rockwell hardness test, an indenter is pressed into the material. . HRA: 20 to 88; HRB: 20 to 100; HRF: 60 to 100; Advantages and disadvantages. The advantage of Rockwell hardness testing is the relatively short testing time and good automation capability, as the measured values are determined directly from the indentation depth .

For example, a hardness value of 70 on Rockwell scale A is written 70 HRA. The Rockwell hardness test's primary advantage is that you get the hardness values directly without doing the tedious calculations common in other testing .Rockwell hardness A HRA Conical diamond 98.07N (10kgf) 588.4N (60kgf) 20-95HRA . 20.6”(523mm) x 9.25” (235mm) x 30.7”(780mm) 20.6”(523mm) x 9.25” (235mm) x 30.7”(780mm) . *Dedicated to the Rockwell Superficial hardness test V-anvil (small) 810-041 (Outside ø40 mm, Groove width 6 mm)Rockwell HRB Vickers HV N/mm²; 3000kg 10mm Ball 150kg Brale 100kg 1/16" Ball . Diamond Pyramid 120kg. Tensile strength (Approx) Reference table: Steel Hardness conversion chart. Since the various types of hardness tests do not all measure the same combination of material properties, conversion from one hardness scale to another is only an .Rockwell Hardness Test Blocks HRA, HRB, HRC Hardness testing blocks are designed for metals hardness testers calibration. There are available different standard nominal values of the blocks, such as: 25 HRC, 45 HRC, 65 HRC, 90 HRB, 83 HRA.

Ordinary versus superficial In reality, there are two separate kinds of Rockwell test procedures. The Regular method and the Superficial method are these. The Regular technique is often referred to as the Rockwell method (AKA Super Rockwell method). 1. The Usual Approach Since this is how the Rockwell test is often conducted, 10 kgf is [.]

rockwell hardness testing standards

That’s why these standards formulate tables for conversion process, with test load and hardness ranges. Here are the hardness tables and conversion charts for you. + 86 755 61301520 The calculator has two modes — calculate and convert.The calculate mode is helpful if you have the indentation depth and want the Rockwell hardness number for either scale B or C. The convert mode is for converting Rockwell hardness numbers to a different scale like Brinell or Vickers.. The hardness data can not be presented in terms of a universal .

For instance, a hardness value of 80 on the Rockwell A scale is denoted as 80 HRA. When choosing a Rockwell scale, a general rule of thumb is to pick the scale that identifies the biggest load and the biggest indenter possible without going beyond identified operation conditions and considering conditions that may have an impact on the test .Rockwell [HRC /HRB/ HRA] is one of the most common units used for listing the hardness of machined materials. The test is done by measuring the depth of penetration of a sphere under a large load compared to the penetration made by a reference preload. The Rockwell scale is divided into 9 sub-scales marked by letters A-K. Each scale uses a .The Rockwell hardness test continues to be applied as a tool for assessing . increase in the preliminary-force for a Rockwell HRA test... 16 Figure 3: Force vs. time plot (Figure A) and indenter-depth vs. time plot (Figure B) demonstrating the effect of an . test surface of 25 HRC test blocks, illustrating how

The connection between hardness and carbon content is clearly visible in the example below: the higher the carbon content, the higher also the HRC of various types of White Steel: White Steel 1 / 63 HRC / C = 1.25-1.35 % White Steel 2 / 61-62 HRC / C = 1.05-1.15 % White Steel 3 / 60 HRC / C = 0.80-0.90 % Measuring hardness There are several .

4.3 Verification of the indenter 4.3.1 Diamond cone indenter (scales A, C, D, N) To verify the reliable performance of the conical indenter in conformance with this part of ISO 6508, a directHardness testing blocks, made of carbon steel are used to calibrate metal hardness testers and come in various standard nominal values, such as 25 HRC, 45 HRC, 65 HRC, 90 HRB, and 83 HRA. Total: $ 0.00

1999 twin cam compression test

WEB19K Followers, 694 Following, 61 Posts - See Instagram photos and videos from pampam (@pamella_makeup_pampam)

rockwell hardness test hra of 25|rockwell hardness chart